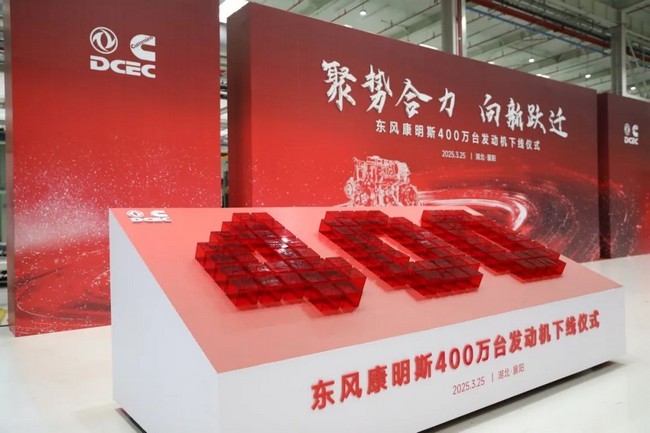

On March 25, with a brand-new Z15N FE natural gas engine slowly rolling off the production line, Dongfeng Cummins Engine Co., Ltd.(DCEC) reached another important milestone in its development history – the official roll-off of its 4 millionth engine.

Since 1986, taking technological innovation as its core driving force, DCEC has developed engine, transmission and power chain technologies in synchronization with the European and American markets, contributing to a leapfrog improvement in the manufacturing technologies of domestic light, medium and heavy-duty engines. In 2007, the 1 millionth engine rolled off the production line; in 2013, the 2 millionth engine rolled off the production line; in 2019, the 3 millionth engine rolled off the production line; in 2025, the 4 millionth engine rolled off the production line… Over the past 39 years, the displacement of Dongfeng Cummins’ products ranges from 2.5 liters to 15 liters, and they are widely applied in fields such as commercial vehicles, construction machinery and power generation equipment, becoming the “wealth-creation partners” of millions of users.

Huang Haitao, General Manager of DCEC, introduced that behind the 4 million engines is the trust and choice of 4 million users in more than 130 countries and regions around the world. DCEC will closely focus on the three core strategies of “Green Power, Intelligent Manufacturing, and Global Collaboration”, continuously deepen its presence in the diesel engine and natural gas engine markets, accelerate the expansion of its transmission and new energy businesses, and strive to build DCEC into a provider of integrated power assembly solutions and a global manufacturing base of Cummins.

To transition from a manufacturing powerhouse to a manufacturing superpower, intelligent manufacturing is the inevitable path. To keep up with the trends of the times, DCEC established an intelligent manufacturing plan at an early stage and carried out technological transformation and intelligent upgrades of the entire production line. In 2019, the National VI engine flexible assembly line was officially put into production. In 2020, the construction of the heavy-duty engine manufacturing line was launched, and intelligent logistics solutions such as stereoscopic warehouses and AGVs were introduced. In 2023, the heavy-horsepower intelligent factory was put into production, marking a solid step forward in the field of digitalization and intelligent manufacturing.

The heavy-horsepower intelligent factory adopts advanced manufacturing technologies and digital application scenarios, such as intelligent logistics, automatic docking of test benches, fuzzy grasping by robot vision, AI visual inspection, etc. In terms of “green intelligent manufacturing”, the AGV material distribution technology is applied. The photovoltaic roof project has greatly reduced the energy consumption of public power. The application of the dry paint spraying booth has achieved zero discharge of water pollution in spraying. This series of automated, flexible, green and intelligent production innovations has not only brought about a qualitative leap in the production efficiency of DCEC but also comprehensively improved the product quality!

For DCEC, the roll-off of the 4 millionth engine is not only a powerful testament to its past brilliant achievements but also a brand-new starting point for its future development. It will surely further consolidate Dongfeng Cummins’ position in the internal combustion engine field and lay a solid foundation for its future development.