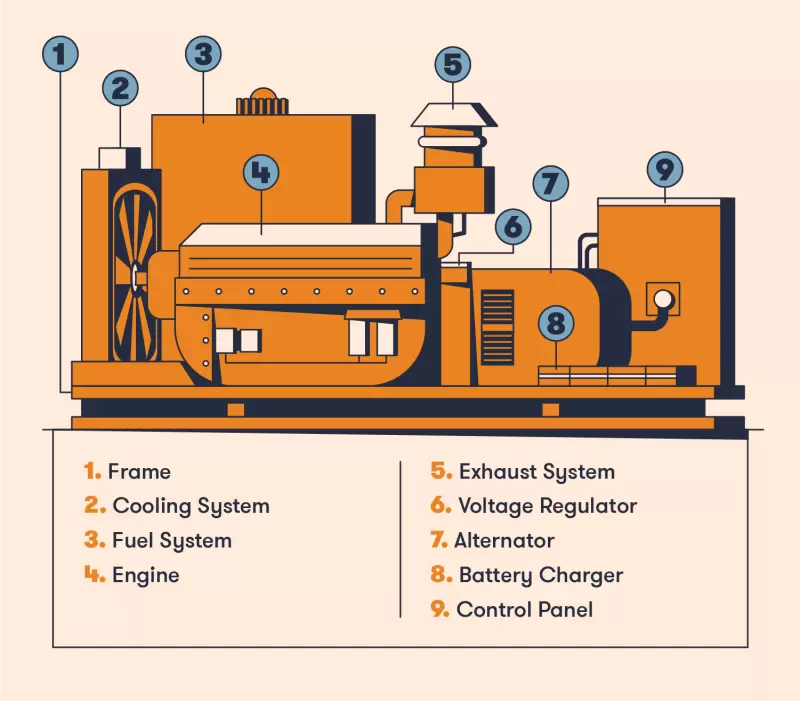

1. Working Principle:

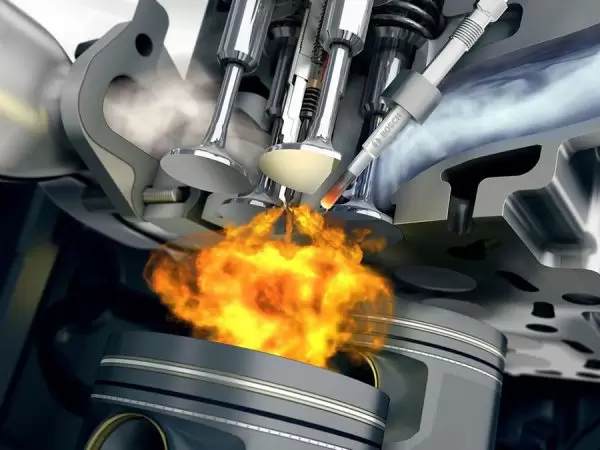

The diesel engine drives the generator, converting the energy of diesel fuel into electrical energy. Inside the diesel engine cylinder, clean air filtered by the air filter mixes thoroughly with high-pressure atomized diesel fuel injected by the fuel injector. Under the compression of the upward-moving piston, the volume decreases and the temperature rises rapidly, reaching the ignition point of diesel fuel. The diesel fuel is ignited, the mixture burns violently, and the volume expands rapidly, pushing the piston downward, which is called ‘work’. Each cylinder performs work in a certain sequence, and the thrust acting on the piston is converted into a force that drives the crankshaft to rotate through the connecting rod. By installing a brushless synchronous AC generator coaxially with the diesel engine crankshaft, the rotation of the diesel engine can drive the generator rotor. Utilizing the principle of ‘electromagnetic induction’, the generator outputs an induced electromotive force, which generates current through a closed load circuit. This only describes the most basic working principle of the generator set. To obtain usable and stable power output, a series of diesel engine and generator control and protection devices and circuits are also required.

2.Pre-power-on checks:

( 1 ) Confirm that the control switch / key switch is in the off position.

( 2 ) Check the engine oil and coolant levels; add more if necessary.

( 3 ) Check the fuel level in the fuel tank and add fuel if necessary.

( 4 ) Check the condition of the engine fan and the tension of the charger belt, and tighten them if necessary.

( 5 ) Check all conduits to see if any connections are loose or damaged. If so, tighten or replace them.

( 6 ) Check the battery electrodes for corrosion; if so, clean them.

( 7 ) Check the air filter and replace it if necessary.

( 8 ) The area around the generator set should be kept clean, and unsafe objects should be removed to avoid affecting operation or causing danger. Ensure that the ventilation ducts of the machine room are not blocked.

( 9 ) Check the unit’s fuel system, cooling system and lubrication system for leaks.

( 10 ) Check that all valves in the oil pipeline are in the open position.

3. Startup:

( 1 ) Complete the pre-power-on checks

( 2 ) Connect the battery to the engine starter motor.

( 3 ) Start the engine lubrication system

( 4 ) Use a hand pump to pump fuel into the fuel system to remove air from the fuel lines.

( 5 ) Start-up: The unit should not be started for more than 5-7 seconds. If the start-up fails, the unit should be stopped for 10 seconds before trying to start again. If the start-up fails 4 times, please refer to the fault guide to find the cause of the start-up failure.

( 6 ) After the unit starts up, check whether there is any abnormal noise or vibration.

( 7 ) Check the unit’s exhaust system for gas or liquid leaks.

( 8 ) Check the control panel display for any abnormal indications, especially the water temperature, oil pressure, and oil temperature displays.

( 9 ) Check the voltage and frequency through the control panel display.

( 10 ) Once the unit has generated voltage, check if the phase is correct.

( 11 ) If there are no problems with the above, you can connect the load cable and prepare for normal power generation shutdown: you must disconnect the air switch first and then disconnect the starting battery circuit.